At Lightning Bay Pneu-Draulics, our capabilities are nearly endless. We have expert service technicians that have a passion for getting the job done right. With highly skilled laborers, top-of-the-line equipment and creative minds, we are capable of just about anything.

From local to worldwide we test, troubleshoot, install, remanufacture, and redesign hydraulic cylinders, gearboxes, valves, winches, and more. Our capabilities surpass others and our fabrication is completed in-house.

Hydraulic Service & Capabilities

Tube & Pipe Bending

- 2.5″ Pipe

- 2″ Tube

- 5″ Pipe (shop bending)

- 304, 310. & 316 Stainless & Carbon Steel Pipe, Stainless Steel & Dichromate Zinc Tube

Field/Shop Hose Crimping

- 2″ 6-Wire High Pressure Hoses

Flushing & Filtering

- 150 GPM High Pressure Flushing

- Hydraulic & Gear Oil Filteration

Lifting

- 30,000 LB Shop Overhead Crane

- 8,600 LB Truck Mounted Crane

- 6,500 LB Truck Mounted Crane

- 4,000 LB Truck Mounted Crane

Cylinders and Presses

Our technicians can go to your site to troubleshoot hydraulic presses, balers and compactors at times convenient to your production.

Remanufacturing:

Using our custom-designed cylinder maintenance table, we can completely remanufacture cylinders of any size maintaining OEM specifications.

Presses, balers, & compactors:

If the machine can be transported for remanufacturing we can haul it for you or you can freight it to our facility.

Testing:

Static and dynamic testing up to 10,000 psi with a 200 gallon test bench for even the largest of bores and strokes.

Field Service:

Our service trucks are fully equipped so that we can safely troubleshoot, remove and install cylinders on site. We work with the following:

- Hydraulic & pneumatic cylinders (NFPA/Metric)

- Mill type cylinders

- Tie rod cylinders

- Large bore cylinders

- Telescoping cylinders

- Multi-stage cylinders

- Mobile/heavy equipment

- Rod straightening

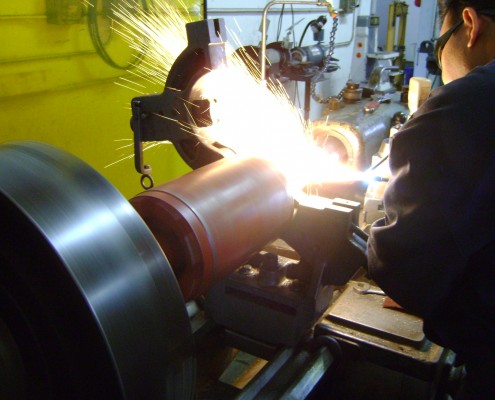

- Grinding

- Polishing

- Bore welding, honing and sizing

- Chrome services available

- Complete machining and welding capabilities

Gearboxes and Winches

Remanufacturing

Gearbox remanufacturing can be an efficient way to ensure your company remains profitable. Along with being cost-effective, our delivery time is often much shorter than a new unit which reduces your down time. We offer a one-year warranty and can extend onsite removal and installation. Our list includes:

- Shaft remanufacturing

- Broaching and Key Seating

- Gear Contact and Mesh Testing

- Gearbox Testing

Gearboxes we specialize in:

- Amarillo

- Boston Gear

- Brevini

- Cleveland

- Dodge

- Fairfield

- Falk

- Gear Products

- Heco

- Hub City

- Lightnin

- Marley

- Ohio Gear

- Philadelphia Gear

- Rexnord

- RR Gearbox

- Von Ruden

Winches we specialize in:

- Anchor Windlass

- Braden

- Capstan

- DP Winch

- Gear Products

- Ingerson Rand

- Gearmatic

- Intercon

- Lantec

- Markey

- Modring

- NETEC

- Pullmaster

- Yokohama

Heavy and Mobile Equipment

We repair and have remanufacturing services for:

- Kaiser/Menzi Muck

- Challenger tractors

- Excavators

- Dozers

- Mi-Jack straddle cranes

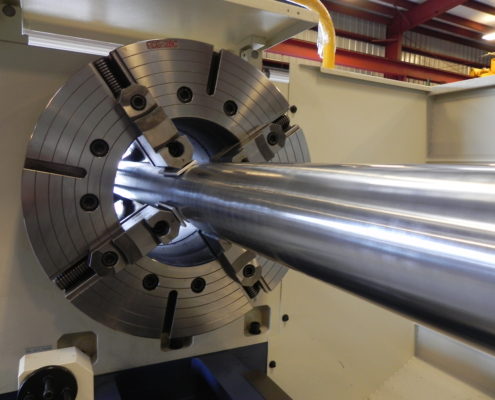

Machining

Our Shop:

Our facility has a full service machine shop where we can reverse engineer new product using specifications from old or damaged pieces or custom make new pieces from drawings.

Knee Mill:

- Summitt Mill – 10” x 50” table

- Vectrax Mill – 12″ x 60″ table

Summit Manual Lathe:

- Summitt 69″ Swing x 320″ Centers

- Summit 26″ Swing x 160″ Centers

Leblonde Slide Bed Lathe:

- 20” chuck x 24” swing x 140”L

- 40” chuck x 40” swing x 60”L

American Lathe:

- 22” swing x 150″ Centers

Harrison Lathe:

- 17” Swing x 40” Centers

- 14’ Plate Shear

Align Boring:

- Shop and field services

- Heavy/Mobile equipment attachments

- Concentric bearing journals

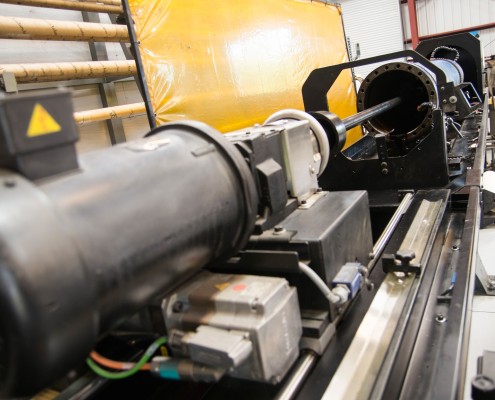

Honing services:

- Bore sizing & Honing

- Cross hatch surfacing

- Sunnen PLC Controlled Honing Center 36″ Bore x 40′ long

Surface Grinding

- Brown & Sharp 8″ x 24″

Lap Master Valve/Pump Lapping Machine

- 28″ Capacity

- 10″ Capacity

Welding and Fabrication

Along with certified fluid power technicians and machinists, Lightning Bay Pneu-Draulics also has certified welders to ensure that we do not have to outsource and keep your costs down. Custom fabrication is what we do and quality service is what you will get.

- Piranah Iron Worker – 50 Ton

- Shearing 0- Cincinnati Century 1/2″ x 12′ Hydraulic

- Rolling Services – Roundo R5, Channel, Beam, & Angle Iron Welding

All certified welding all processes include:

- MIG, TIG, ARC, Stick, Brazing

All metals, such as, stainless steel, aluminum and cast fabrication/welding services include:

- Plasma cutting

- Oxygen lance cutting

- Roll bending – shapes, structural and pipe

- Shearing – ½” x 14’, 50 Ton Piranah Iron Worker

- Spray welding

- Microbonding/metalizing

- Arc gouging

Pumps, Motors and Valves

Knowing how important it is to keep your systems running, every unit we remanufacture is tested in our shop to OEM specifications with a one-year warranty.

Remanufacturing:

Our experience and capabilities allow for us to troubleshoot and remanufacture various types of open and closed loop hydraulic pumps and motors. We work with:

- Open and closed loop components

- Hydrostatic transmissions

- Variable and constant displacement pumps and motors

- Control options – Pressure compensated, horsepower limiting, load sense

- Gear, piston, vane and poppet

Field Service:

- On-site troubleshooting, removal, installation and start ups.

Testing Capabilities:

- 6,000 psi, 200 gpm

- 5 Section/Multi Stage Pump Testing

Pumps we specialize in:

- Bosch, Commercial, Continental, Denison, Dynapower, Dynex, Eaton, Hydura, Kawasaki, Linde, Mitsubishi, Oilgear, Parker, Permco, Racine, Rexroth, SauerDanfross, Sundstrand, Tyrone and Vickers

Motors we specialize in:

- Cessna, Char Lynn, Commercial, Eaton, Feroy, Hagglands, Helac, KYB, Linde, Mactaggart Scott, Nichols, Norseman, Parker, Poclian, Rexroth, Rineer, Ross, Rotary Power, SauerDanfoss, Staffa, Sunstrand, Tyrone, Vickers, Volvo/Voac, Von Ruden and White

Tubing, Hose and Pipes

We offer on-site hose, tubing and hydraulic pipe installation that best fits your system. We use only high quality, American-made Goodyear and Aerquip hoses for your hydraulic needs.

On-site hydraulic hose, tubing and pipe fabrication and installation includes:

- High Pressure 6-wire hydraulic hoses

- “Lokring” tooling and installation by a specialist

- Tube and pipe bending by experts

Socket and butt welds include:

- Carbon steel

- 304 and 316 stainless seamless tube

- 310 stainless steel pipe (Sulfuric Acid, steam, and high temperature)

- P.O.P. Pipe – Pickled, Oiled and Plugged

Fluid power conductor and connector experts in:

- JIC flaring, compression, swedgelock tooling and Lokring

- American/Standard, Metric, British, Japenese & European

Cooling Towers

Our technicians can troubleshoot and repair all aspects of your cooling tower; including major rebuilding, overhaul, minor repair and inspection services.

Testing

Cylinder Test Stand

- 10,000 PSI

- 400 Gallon Reservoir

Pump & Motor Test Stand

- Open & Close Loop

- 200 SPM

- 6000 PSI

- 100 HP Test Station

- 200 HP Test Station

- 5 Stage Pump Testing