Full Service Machining, Fabrication & Assembly

From large scale Horizontal Boring Mill (HBM) to Machining projects, we can help. Need complete Machinery Building Services? We can do that, too.

We are a full service hydraulic and mechanical shop, complete with a substantial machine and fabrication shop. These capabilities enable us to manufacture or repair hydraulic and pneumatic cylinders and repair valves, pumps, motors, gear boxes and other hydraulic or complex mechanical equipment. We are particularly skilled at replicating hard to find parts or repairing machinery no longer supported by the original manufacturer.

Customer Service is Our Priority

Any service we provide to our customers that have any mechanical issues within one year of service, we will repair or replace our workmanship at no charge.

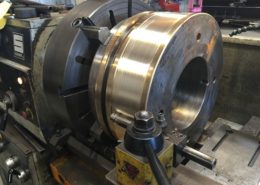

Hydraulic Services

Hydraulic Services

Complete repair, remanufacture and testing hydraulic and pneumatic components. The caliber of work that we do allows us to offer our customers a one year warranty.

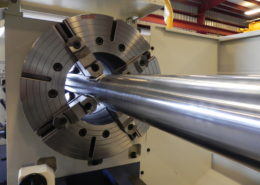

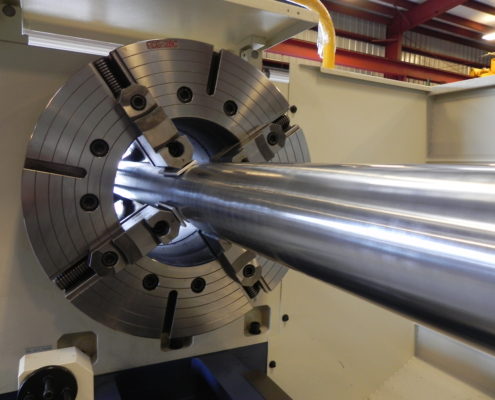

Machine Turning

Machine Turning

Precision turning and facing of small and large shafts, we are highly proficient when it comes to lathe work.

Precision Milling

Precision Milling

Whether your requirements include complex 3D contours or simple drill and tap projects, we provide a full spectrum of million processes.

Welding & Fabrication

Welding & Fabrication

Certified welders with all the right equipment are available to help with your most challenging welding, assembly and fabrication projects.

Re-Manufacturing

Re-Manufacturing

Our experienced technicians can help with your equipment rebuilding, reconditioning, or complete overhaul services requirements.

Testing

Testing

Our full service machine shop ensures top notch quality control for your components and systems. All cylinders, pumps and motors are tested before they leave our facility.

Full Line of State-Of-The-Art Equipment

Machining & Turning Capabilities • Manual Machining Capabilities • Welding and Fabrication • Short Run Productions • Honing • Value Added Services

Whatever the job calls for, Lightning Bay Pneu-Draulics can ensure that all related services are done to specifications and are of the highest quality.

Leading Edge Technology

Leading Edge Technology

Leading edge technology and our experienced machinists, along with a dedication to customer service, helps us to produce quality work that sets us apart from other machine shops in the area. If you have a machining (milling or lathe turning), welding or fabrication project … contact Lightning Bay Pneu-Draulics … we will work with you to provide you with the best product possible that meets your requirements.

Summit dealer Southern Machine Tool Rebuilders assisted with the installation and most recent purchase of the largest lathe in Lightning Bay’s shop, the Summit 42-14×360 manual lathe. The length and size of the machine made for a tricky installation. Steve Wendrick of Southern Machine Tool Rebuilders carefully planned and executed the difficult task.

Since trusting Summit with their business in 2012, Faye and his team at Lightning Bay have grown their Summit machine force from one to four machines. They confess their most valuable Summit machine is the 24-4×160 manual lathe. “But all are valuable to the company and our customers,” says Faye. “Without each one, we would not be able to provide the full array of services we currently offer.”

Check out the Lightning Bay customer spotlight from Summit Machine here